- Motor winding system for free#

- Motor winding system generator#

- Motor winding system verification#

- Motor winding system software#

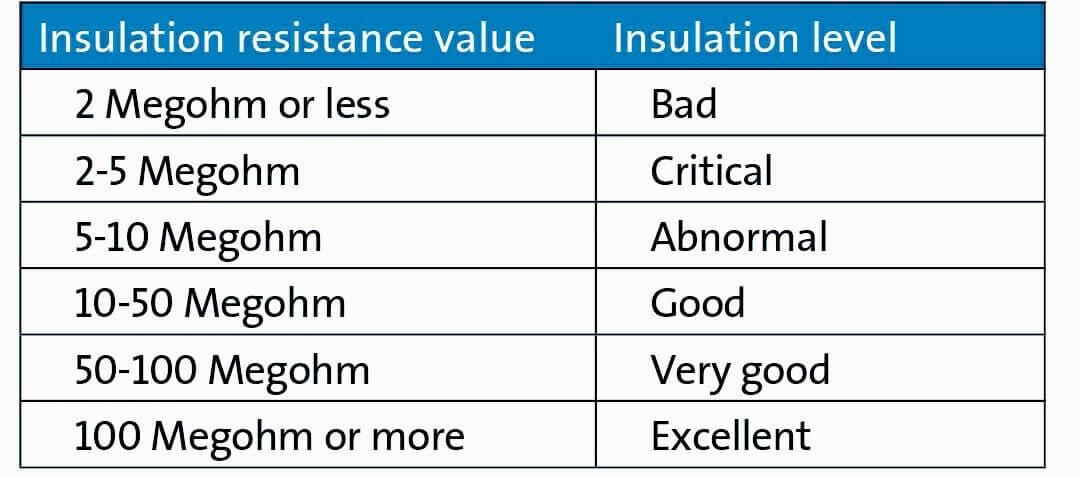

Moreover, this technique can be used when in-place and non-destructive trending of the electrical motors is performed. This is why winding analysis should remain as one of the key components of predictive maintenance operations. For this reason, it helps to perform motor winding analysis to eliminate this concern. Motors can be spared from premature failure and the winding insulation’s dielectric strength can be determined at the same time. Motor windings can be a huge problem with equipment. Business owners can continually find ways to cut costs by maintaining the excellent condition of equipment that will impact the bottom line. Maintenance costs will also be reduced to a minimum as potential issues are detected before they become apparent. This allows motor failures to be minimized and productivity losses avoided. Through winding analysis, critical tests to identify the existing motor winding insulation must be performed. Through motor current analysis, it is easy to determine when the electric winding insulation malfunctions. These include mechanical and environmental conditions, serious faults and power supply issues. Aside from this, operating conditions that often lead to winding failure on electric motors will be determined. Motor winding analysis serves as the initial step to setting a baseline relevant to the life of electric motors. The information acquired is also more in-depth and sophisticated. It may be performed in addition to motor current analysis, and the electric winding insulation can be classified at the same time.

Motor winding system generator#

Winding analysis is a non-invasive type of testing motors, as well as generator and transformer windings. Check these areas most and assess and/or avoid potential issues before they occur or get worse. 4.Keep in mind that certain factors can increase the workload or strain on the motor, such as the cycling variation, load and environment.

Motor winding system verification#

Note: The Motor Winding Database is included in EASA's AC Motor Verification & Redesign - Ver. (Note: The local database does not receive updates.)

Motor winding system software#

If your computer does not have an Internet connection, the software will automatically switch to the static, local database that was included and loaded during installation. Using the online database guarantees you’ll have the most up-to-date information available at all times. This live database will be continuously monitored, updated and corrected as needed by EASA’s Technical Support Staff. Most notably, it now has the ability to connect to a live, ever-expanding online database of more than 250,000 windings. This version of the EASA Motor Rewind Database software takes a large leap forward with the data that it provides members. EASA's Motor Rewind Data software SHOULD NOT be installed if you are already using EASA's AC Motor Verification & Redesign.

Motor winding system for free#

This valuable resource is available only to EASA Members.ĮASA members can download this software for FREE using the link below! NOTE: The Motor Rewind Data winding database is included in EASA's AC Motor Verification & Redesign - Ver. Getting the Most from Your Electric Motors.Failures in Three-Phase Stator Windings.Don't wait to save your place at the 2022 Convention & Solutions Expo.ĮASA's international membership is divided into 10 Regions that are made up of 32 Chapters. It's not too early to reserve your room at one of EASA's official St. Find a service center that has proven they repair electric motors in accordance with ANSI/EASA's AR100.

0 kommentar(er)

0 kommentar(er)